Products You May Like

The Roscosmos space agency provided financial support to Aleph Farms’ experiment of cultivating meat in space.

Roscosmos

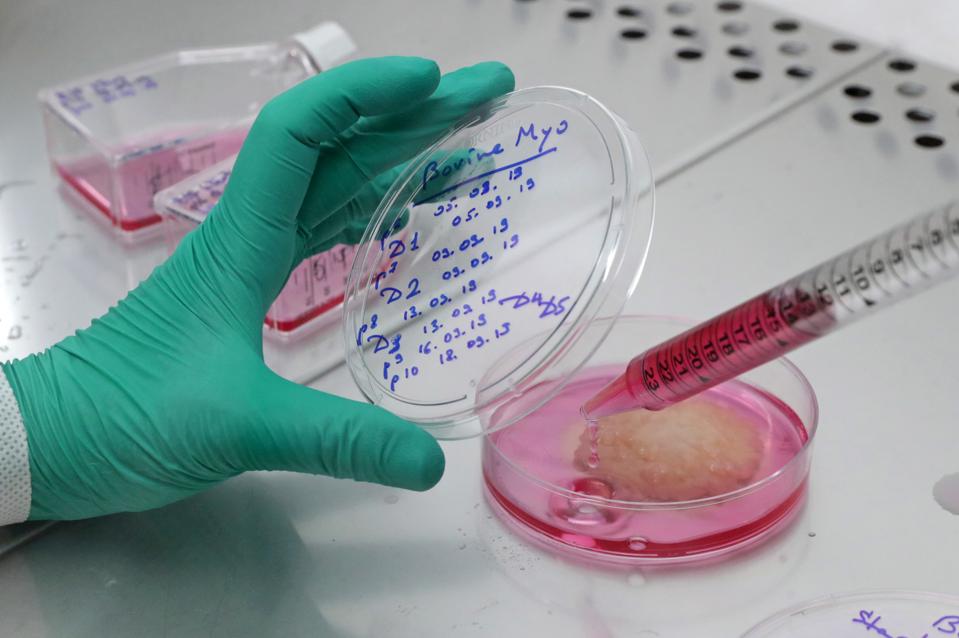

Israeli start-up Aleph Farms made international headlines this month by announcing that it has successfully grown meat from bovine cells in space. While the move is a publicity stunt to many, the Russian technology company that helped facilitate the experiment with its own equipment said boosting food sustainability on Earth is at the core of this breakthrough.

Moscow-based 3D Bioprinting Solutions, the R&D subsidiary of Vivax Bio, is primarily focused on developing the whole range of the hardware, materials, technologies and products comprising the 3D bioprinting industry.

CEO Yusef Khesuani noted he has been working with animal cells since the inception of the company around 2013, but the team only began to apply its expertise in the field of bioprinting to cellular agriculture recently.

“Long-term manned space stations are bound to face unparalleled challenges with nutrition and reutilization of all available organic resources,” he told me via an email.

“As a company, which has gained a lot of experience and expertise with both bioprinting and space-related engineering designs, we believe that biofabrication of cultured meat in space has several unique advantages,” especially around sustainability and ethicality.

He believes experiments, such as the one conducted with Aleph Farms, are a “stepping stone towards sustainable production of cultured meat products during deep space expeditions and initial colonies on the moon and Mars”.

Human cartilage tissue and rodent thyroid gland

3D Bioprinting Solutions has previously developed Organ.Aut magnetic bioprinter and magnetic bioprinting technology, with the former delivered to the International Space Station (ISS) on board the Soyuz MS-11 manned spacecraft to start bioprinting experiments about a year ago.

“For the first time on orbit, a cosmonaut researcher printed human cartilage tissue and a rodent thyroid gland using a bioprinter,” Khesuani said. “Our magnetic bioprinter became a permanent part of the ISS scientific equipment, enabling us to provide it as infrastructure for a wide range of biotechnology experiments.

“We intend to use our proprietary 3D bioprinting technology and tools as a platform to focus on cell-based cultured meat/fish project, while still further developing our 3D bioprinting technology.”

He noted 3D Bioprinting Solutions approached Aleph Farms in 2018 after realizing the company’s co-founder Dr. Shulamit Levenberg has a similar background in biotechnology, therefore, “we introduced both of our cutting-edge extrusion bioprinter FABION, along with Organ.Aut and magnetic bioprinter, to Aleph Farms”.

Cultured meat market

Aleph Farms’ announcement comes as the global cultured meat market is growing at an accelerate rate to meet the increasing consumer demand for ethical meat products made with minimum environmental damages.

Didier Toubia is the co-founder and CEO of Israeli cultured meat start-up Aleph Farms.

Afik Gabay

MarketsandMarkets estimates the revenues of the global meat market to be $214 million in 2015, and to reach $593 million by 2032, growing at a 15.7% CAGR during the forecast period.

The research firm said “health concerns about the consumption of meat products and increased investor interest in alternative proteins” are also driving the growth of the cultured meat market, of which North America will account for the lion share in terms of value by 2021 due to the rise of innovations and developments.

Another Israel-based cultured meat specialist Future Meat Technologies recently secured a $14 million round of funding led by S2G Ventures and Emerald Technology Ventures. Founder and chief science officer Yaakov Nahmias is currently using the money to construct a facility, hoping to make the products affordable across Israel by 2021.

However, co-founder and CEO of Aleph Farms, Didier Toubia, believes cultivating meat in space demonstrates several potential benefits.

“Space is one of the scarcest, most hostile and remote environments possible that have nearly no [natural] resources available. The experiment … has demonstrated our capacity to produce food without the reliance on local land and water resources, and then potentially reverse climate change,” he said, noting the UN recently stressed that conventional animal farming methods create a challenging environment that will ultimately undermine food security.

Toubia added: “Intensive animal farming also serves as a major driver of biodiversity loss and contributes to deforestation and fires in the Amazon, and is responsible for the destruction of soils due to monoculture of soy as animal feed.”

The other benefit is that cultivated meat can help avoid potential spoilage of food during transportation or storage since it can be produced anywhere at anytime.

Commercialization challenges

Despite the initial success of growing meat in space, experts believe full commercialization of such products will not materialize in the near term.

MOSCOW, RUSSIA SEPTEMBER 27, 2019: Producing cultured meat in a lab at the Ochakov Food Ingredients Plant (OKPI). Vyacheslav Prokofyev/TASS (Photo by Vyacheslav ProkofyevTASS via Getty Images)

Vyacheslav Prokofyev/TASS

Toubia noted Aleph Farms has only established the framework, the infrastructure and the first milestone for further space explorations in the production of cultivated meat in space, saying that, however, the meat created in the experiment is not ready for consumption yet.

“[Our] focus at this stage was on establishing the cell-cell contacts, the structure and the texture of muscle tissues,” he noted.

Additionally, organizing delivery of the cell material to orbit is costly, making it difficult to produce meat in space on a large scale, according to Khesuani.

“Fortunately, our partners at Roscosmos, the Russian space agency, look forward to expanding the range of scientific experiments conducted on the Russian segment of the ISS, and they were eager to offer their assistance, both scientific and organizational, for this experiment,” he said.

“We believe that this space experiment is intrinsically linked to the development of cellular agriculture, the cultured meat in particular here on Earth, and the scientific insights gained from its results will allow the whole industry to reach market earlier.”